The short video above summarizes the multiple engineering challenges involved in relying on wind and/or solar power. Real Engineering produced The Problem with Wind Energy with excellent graphics. For those who prefer reading, I made a transcript from the closed captions along with some key exhibits.

The Problem with Wind Energy

This is a map of the world’s wind Resources. With it we can see why the middle Plains of America has by far the highest concentrations of wind turbines in the country. More wind means more power.

However one small island off the mainland of Europe maxes out the average wind speed chart. Ireland is a wind energy Paradise. During one powerful storm wind energy powered the entire country for 3 hours, and it is not uncommon for wind to provide the majority of the country’s power on any single day. This natural resource has the potential to transform Ireland’s future.

But increasing wind energy on an energy grid comes with a lot of logistical problems which are all the more difficult for a small isolated island power grid. Mismanaged wind turbines can easily destabilize a power grid. From Power storage to grid frequency stabilization, wind energy is a difficult resource to build a stable grid upon.

To understand why, we need to take these engineering

Marvels apart and see how they work.

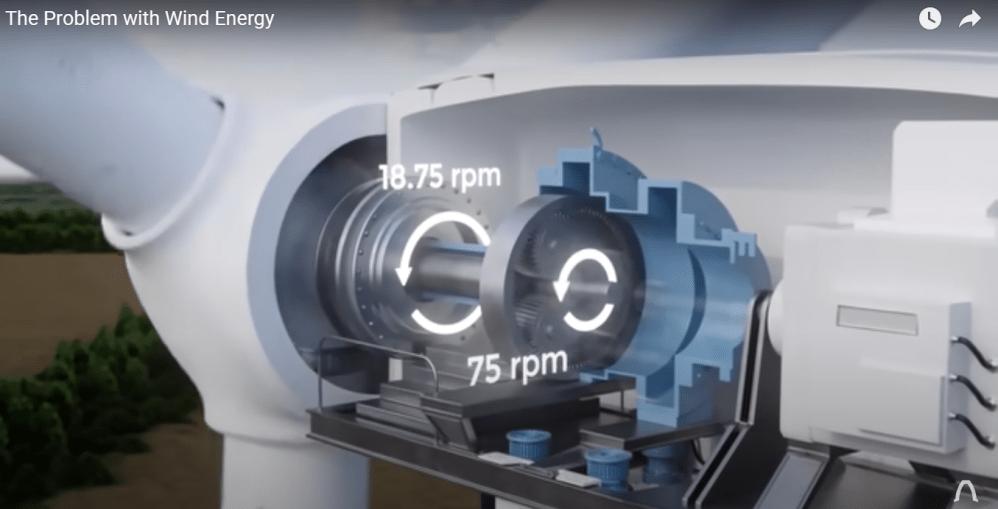

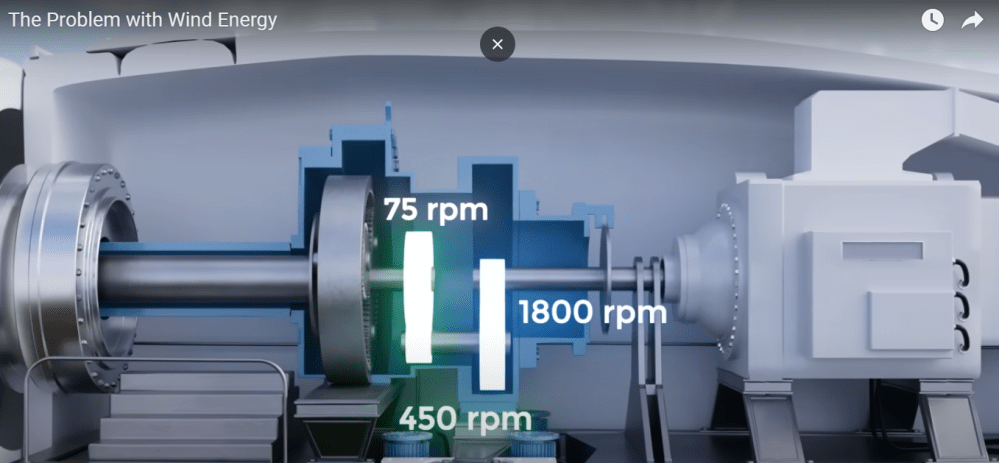

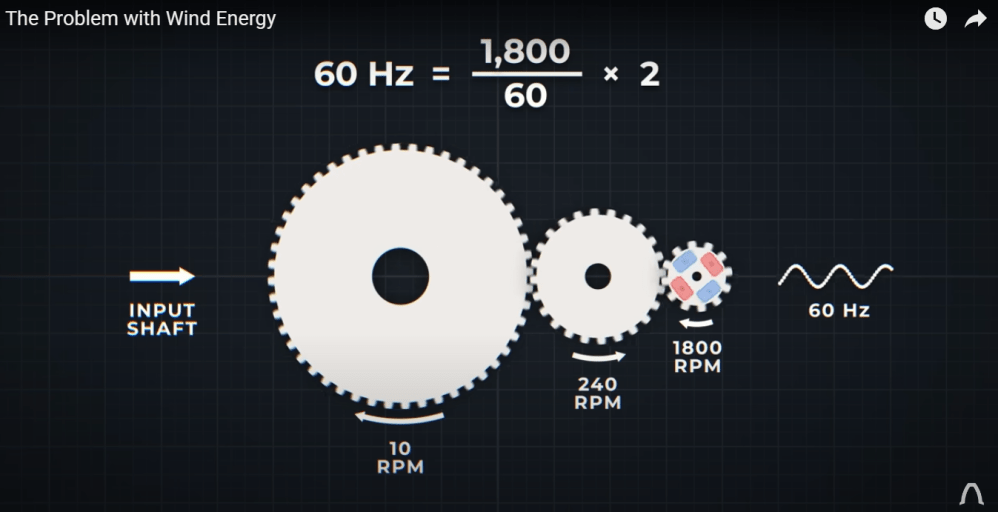

Hidden within the turbine cell is a Wonder of engineering. We cannot generate useful electricity with the low- speed high torque rotation of these massive turbine rotors. They rotate about 10 to 20 times a minute. The generator needs a shaft spinning around 1,800 times per minute to work effectively. So a gearbox is needed between the rotor shaft and the generator shaft.

The gearboxes are designed in stages. Planetary gears are directly attached to the blades to convert the extremely high torque into faster rotations. This stage increases rotational speed by four times. Planetary gears are used for high torque conversion because they have more contact points allowing the load to be shared between more gear teeth.

Moving deeper into the gearbox, a second stage set of helical gears multiplies the rotational speed by six. And the third stage multiplies It again by four to achieve the 1,500 to 1,800 revolutions per minute needed for the generator.

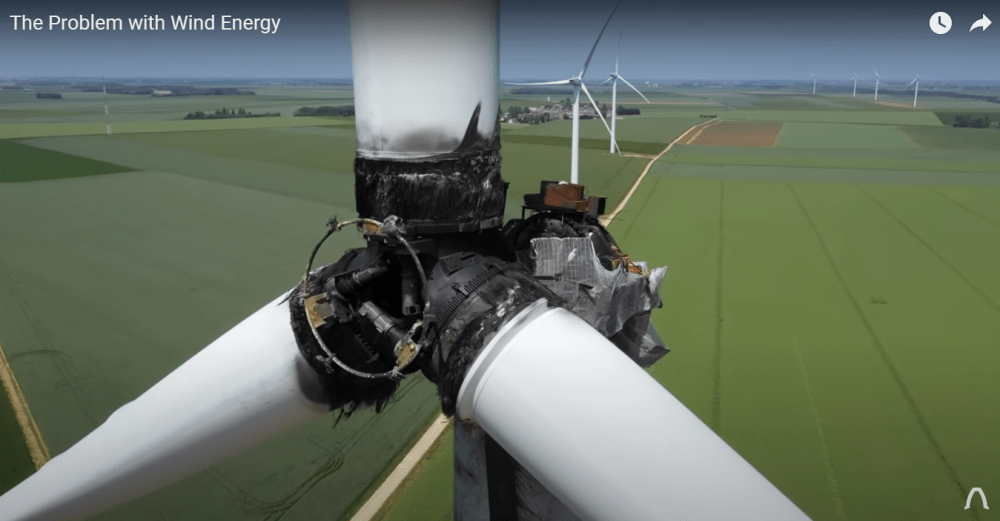

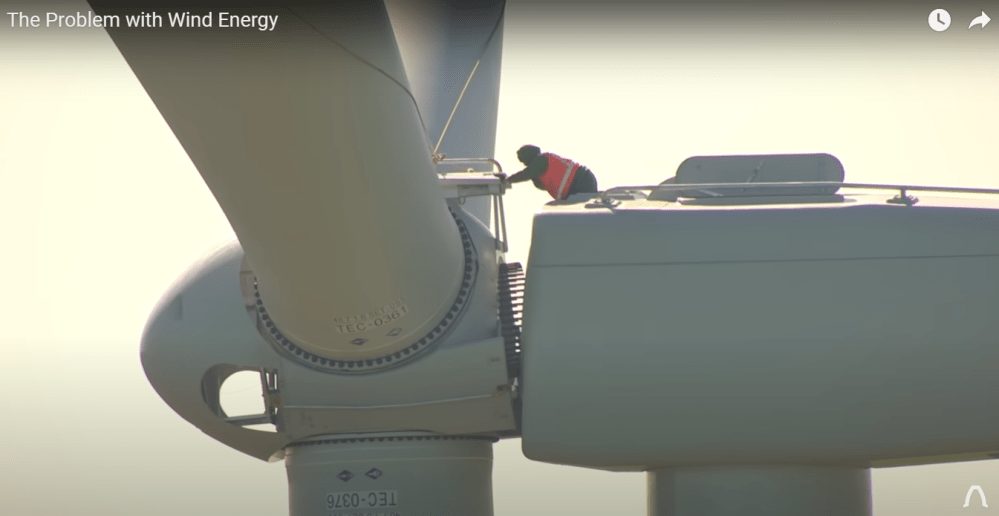

These heavy 15 tonne gearboxes have been a major source of frustration for power companies. Although they’ve been designed to have a 20-year lifespan, most don’t last more than 7 years without extensive maintenance. This is not a problem exclusive to gearboxes in wind turbines, but changing a gearbox in your car is different from having a team climb up over 50 meters to replace a multi-million dollar gearbox. Extreme gusts of wind, salty conditions and difficult to access offshore turbines increases maintenance costs even more. The maintenance cost of wind turbines can reach almost 20% of the levelized cost of energy.

In the grand scheme of things wind is still incredibly cheap. However we don’t know the precise mechanisms causing these gearbox failures. We do know that the wear shows up as these small cracks that form on the bearings,which are called White Edge cracks from the pale material that surrounds the damaged areas. This problem only gets worse when turbines get bigger and more powerful, requiring even more gear stages to convert the incredibly high torque being developed by the large diameter rotors.

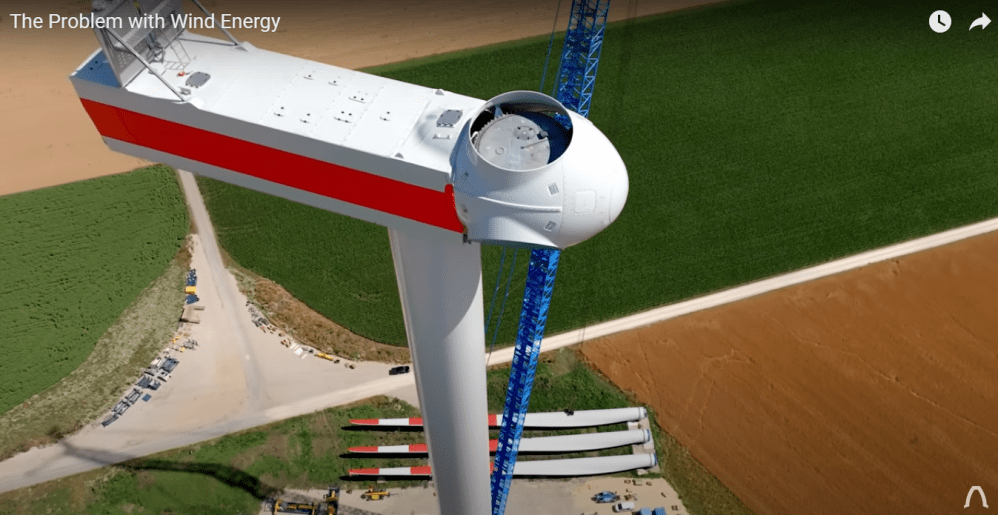

One way of avoiding all of these maintenance costs is to skip the gearbox and connect the blades directly to the generator. But a different kind of generator is needed. The output frequency of the generator needs to match the grid frequency. Slower Revolutions in the generator need to be compensated for with a very large diameter generator that has many more magnetic poles meaning a single revolution of the generator passes through more alternating magnetic fields which increases the output frequency.

The largest wind turbine ever made, the Haliade X, uses a direct drive system. You can see the large diameter generator positioned directly behind the blades here. This rotor disc is 10 m wide with 200 poles and weighs 250 tons. But this comes with its own set of issues. Permanent magnets require neodium and dysprosium and China controls 90% of the supply of these rare earth metals. Unfortunately trade negotiations and embargos lead to fluctuating material costs that add extra risk and complexity to direct drive wind turbines. Ireland is testing these new wind turbines here in the Galway Wind Park. The blades were so large that this road passing underneath the Lough Atalia rail Bridge, which I use to walk home from school every day, had to be lowered to facilitate the transport of the blades from the nearby docks. It takes years to assess the benefit of new Energy Technologies like this, but as wind turbines get bigger and more expensive, direct drive systems become more attractive.

The next challenge is getting the electricity created inside these generators to match the grid frequency. When the speed of the wind constantly changes, the frequency of current created by permanent magnet generators matches the speed of the shaft. If we wanted the generator to Output the US Standard 60 HZ we could design a rotor to rotate 1,800 times per minute with four poles two North and two South. This will result in 60 cycles per second. This has to be exact; mismatched frequencies will lead to chaos on the grid, bringing the whole system down.

Managing grid frequency is a 24/7 job. In the UK, grid operators had to watch a popular TV show themselves so they could bring pumped Hydro stations online. Because a huge portion of the population went to turn on kettles to make tea during the ad breaks. This increased the load on the grid and without a matching increase in Supply, the frequency would have dropped. The grid is very sensitive to these shifts; a small 1 Herz change can bring a lot lot of Destruction.

During the 2021 freeze in Texas the grid fell Incredibly close to 59 Hertz. It was teetering on the edge of a full-scale blackout that would have lasted for months. Many people solely blamed wind turbines not running for causing this issue, but they were only partly to blame, as the natural gas stations also failed. Meanwhile the Texas grid also refuses to connect to the wider North American grid to avoid Federal Regulations. Rather oddly Texas is also an isolated power grid that has a large percentage of wind energy.

The problem with wind energy is that it is incapable of raising the grid frequency if it drops. Wind turbines are nonsynchronous and increasing the percentage of wind energy on the grid requires additional infrastructure to maintain a stable grid. To understand what nonsynchronous means, we need to dive into the engineering of wind turbines once again. The first electric wind turbines connected to the grid were designed to spin the generator shaft at exactly 1,800 RPM. The prevailing winds dictated the size and shape of the blades. The aim was to have the tips of the blades move at around seven times the speed of the prevailing wind. The tips of the blades were designed to stall if the wind speed picked up. This let them have a passive control and keep the blades rotating at a constant speed.

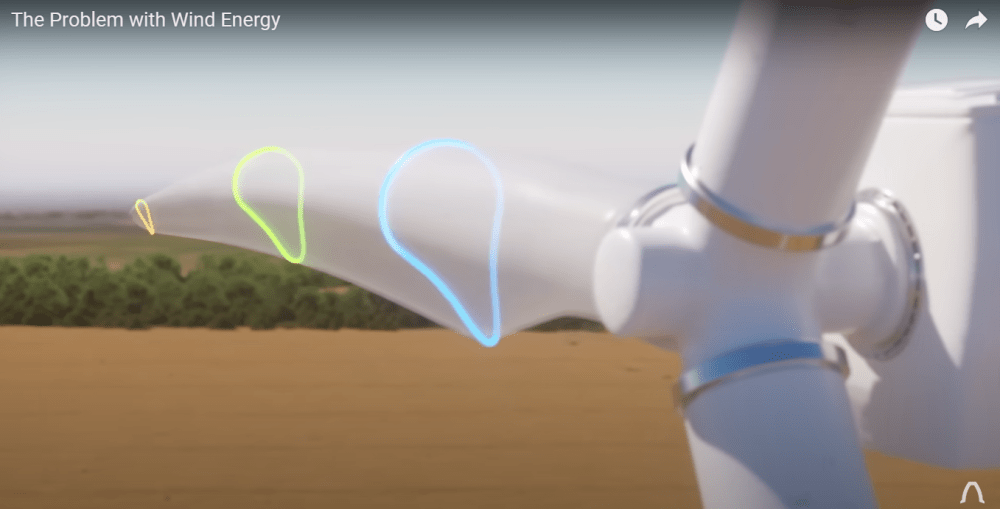

While this allowed the wind turbines to be connected straight to the grid, the constant rotational speed did induce large forces onto the blades. Gusts of wind would increase torque rapidly which was a recipe for fatigue failure in the drivetrain. So to extract more power, variable speed wind turbines were introduced. Instead of fixed blades that depended on a stall mechanism for control, the blades were attached to the hub with massive bearings that would allow the blades to change their angle of attack. This provided an active method of speed control, but now another problem emerged.

The rotor operated at different speeds and the frequency coming from the generator was variable. A wind turbine like this cannot be connected directly to the grid. Connecting a varying frequency generator to the grid means the power has to be passed through two inverters. The first converts the varying AC to DC using a rectifier; then the second converter takes the DC current and converts it back to AC at the correct frequency. This is done with electronic switches that rapidly turn on and off to create the oscillating wave.

We lose some power in this process but the larger issue for the grid as a whole is that this removes the benefit of the wind Turbine’s inerti. Slowing something heavy like a train is difficult because it has a lot of inertia. Power grids have inertia too. Huge rotating steam turbines connected directly to the grid are like these trains; they can’t be slowed down easily. So a grid with lots of large turbines like nuclear power and coal power turbines can handle a large load suddenly appearing and won’t experience a sudden drop in Grid frequency. This helps smooth out sudden increases in demand on the grid and gives grid operators more time to bring on new power sources.

Wind turbines of course have inertia, they are large rotating masses. But those inverters mean their masses aren’t connected directly to the grid, and so their inertia can’t help stabilize the grid. Solar panels suffer from the same problem, but they couldn’t add inertia anyway as they don’t move.

This is an issue for Renewables that can become a critical vulnerability when politicians push to increase the percentage of Renewables onto a grid without considering the impacts it can have on grid stability. Additional infrastructure is needed to manage this problem, especially as older energy sources, like coal power plants, that do provide inertia begin to shut down.

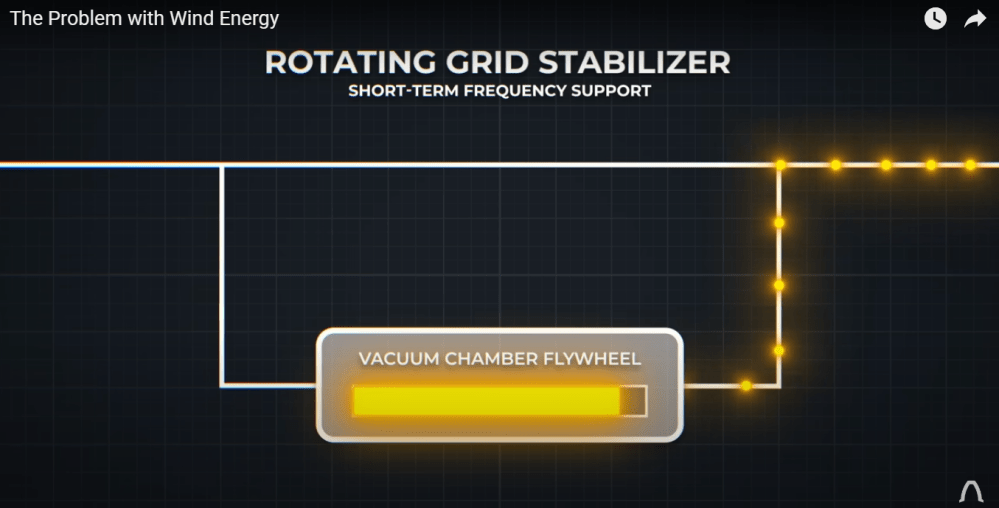

Ireland had a creative solution to this problem. In 2023 the world’s largest flywheel, a 120 ton steel shaft that rotates 3,000 times per minute, was installed in the location of a former coal power plant that already had all the infrastructure needed to connect to the grid. This flywheel takes about 20 minutes to get up to speed using grid power but it is kept rotating constantly inside a vacuum to minimize power lost to friction. When needed it can instantly provide power at the exact 50 HZ required by the grid. This flywheel provides the inertia needed to keep the grid stable, but it’s estimated that Ireland will need five more of these flywheels to reach its climate goals with increasing amounts of wind energy.

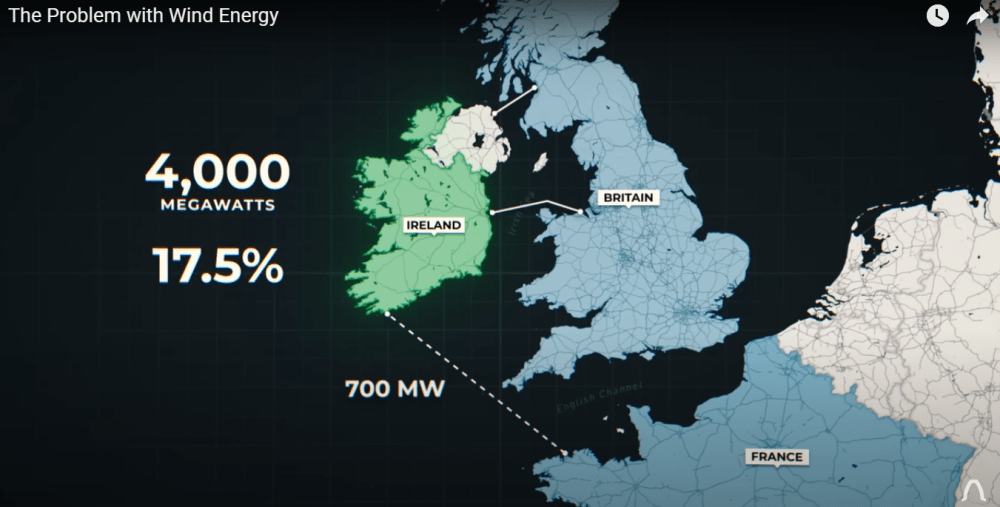

But they aren’t designed for long-term energy storage, they are purely designed for grid frequency regulation. Ireland’s next problem is more difficult to overcome. It’s an isolated island with few interconnections to other energy grids. Trading energy is one of the best ways to stabilize a grid. Larger grids are just inherently more stable. Ideally Ireland could sell wind energy to France when winds are high and buy nuclear energy when they are low. Instead right now Ireland needs to have redundancy in its grid with enough natural gas power available to ramp up when wind energy is forecasted to drop.

Currently Ireland has two interconnect connections with Great Britain but none to Mainland Europe. That is hopefully about to change with this 700 megawatt interconnection currently planned with France. With Ireland’s average demand at 4,000 megawatts, this interconnection can provide 17.5% of the country’s power needs when wind is low, or sell that wind to France when it is high. This would allow Ireland to remove some of that redundancy from its grid, while making it worthwhile to invest in more wind power as the excess then has somewhere to go.

The final piece of the puzzle is to develop long-term energy storage infrastructure. Ireland now has 1 gigawatt hour of energy storage, but this isn’t anywhere close to the amount needed. Ireland’s government has plans to develop a hydrogen fuel economy for longer term storage and energy export. In the National hydrogen plan they set up a pathway to become Europe’s main producer of green hydrogen, both for home use and for exports. With Ireland’s abundance of fresh water, thanks to our absolutely miserable weather, and our prime location along World shipping routes and being a hub for the third largest airline in the world, Ireland is very well positioned to develop a hydrogen economy.

These transport methods aren’t easily decarbonized and will need some form of renewably sourced synthetic fuel for which hydrogen will be needed, whether that’s hydrogen itself, ammonia or synthetic hydrocarbons. Synthetic hydrocarbons can be created using hydrogen and carbon dioxide captured from the air. Ireland’s winning combination of cheap renewable energy abundant fresh water and its strategically advantageous location positions it well for this future renewable energy economy. Ireland plans to begin the project by generating hydrogen with electrolysis with wind energy that has been shut off due to oversupply which is basically free energy.

As the market matures phase two of the plan is to finally begin tapping into Ireland’s vast offshore wind potential exclusively for hydrogen production with the lofty goal of 39 terrawatt hours of production by 2050 for use in energy storage fuel for transportation and for industrial heating. Ireland is legally Bound by EU law to achieve net zero emissions by 2050 but even without these lofty expectations it’s in Ireland’s best interest to develop these Technologies. Ireland has some of the most expensive electricity prices in Europe due to its Reliance on fossil fuel Imports which increased in price drastically due to the war in Ukraine. Making this transition won’t be easy and there are many challenges to overcome, but Ireland has the potential to not only become more energy secure but has the potential to develop its economy massively. Wind is a valuable resource by itself but in combination with its abundance of fresh water it could become one of the most energy rich countries in the world.

Comment

That’s a surprisingly upbeat finish boosting Irish prospects to be an energy powerhouse, considering all of the technical, logistical and economic issues highlighted along the way. Engineers know more than anyone how complexity often results in fragility and unreliability in practice. Me thinks they are going to use up every last bit of Irish luck to pull this off. Of course the saddest part is that the whole transition is unnecessary, since more CO2 and warmth has been a boon for the planet and humankind.

See Also:

Replace Carbon Fuels with Hydrogen? Absurd, Exorbitant and Pointless

3 comments